More Facilities

ESA-certified soldering

In order to reach the needed reliability to withstand space flight, the Institute has ECSS-certified soldering operators with more than 20 years of experience in exploring the solar system.

It is possible to request a quote from us.

Liquid nitrogen production

With a production capacity of 10L/hr, our liquid nitrogen production plant is primarily aimed to support SpaceLab. It is possible though to request a quote from us.

It operates without surveillance and the produced nitrogen is usually used for temperature control or atmosphere purification.

Emergency power supply

In case of an electric power failure, the emergency power supply ensures that work can be smoothly pursued.

Residual Gas Analyzer

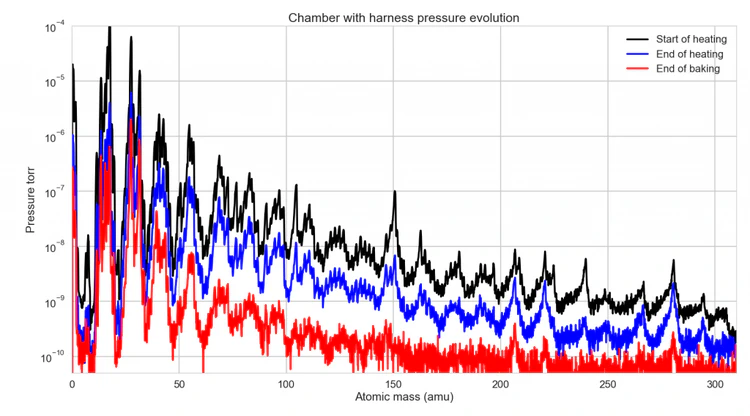

All vacuum chambers can be equipped with a residual gas analyzer (RGA). The RGA measures the residual gas left inside the vacuum chamber and allows to visualize the composition of the residual gas. With several measurements of the RGA taken throughout the test campaign it is possible to compare the residual gas composition throughout the test campaign.

Such a comparison of the RGA measurements during a bake out of a harness for the Jovian plasma dynamics and composition (JDC) analyser is shown in the following figure. As shown, the pressure in the chamber improves over the bake out process and the contribution of heavier masses to the overall pressure is reduced significantly.