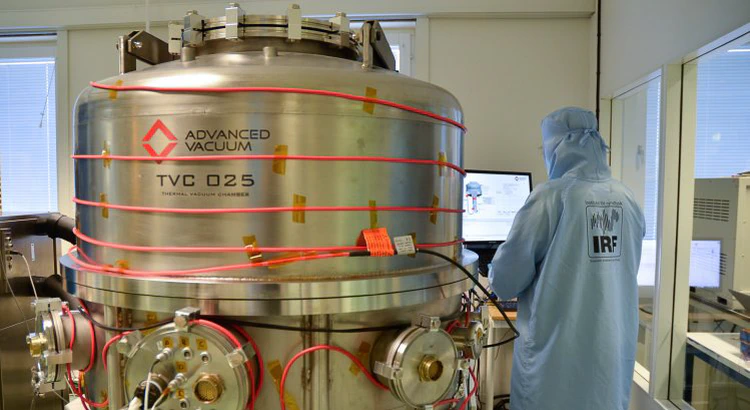

Thermal Vacuum Chamber

Space is a thermally challenging environment as no conductive or convective heat transfer to the the surrounding environment is possible. This leaves only radiative heat transfer, the weakest of the three heat transfer types, to cope with the varying temperatures in space and ensuring that your instrument or satellite survive. It is possible to simulate this environment and the effects of you instrument or satellite and apply the obtained results on Earth in a thermal vacuum chamber. During this thermal vacuum test the survival of your instrument or satellite is proven, as required by all major space agencies.

For smaller items and a quicker turn around time you can also consider using our micro thermal vacuum system, for even bigger items our solar simulator can be considered.

Technical specifications

- Dimensions Chamber (inside)

- $680 mm$ diameter, $426 mm$ height

- Pressure

- <$10^{-7} mbar$

- Temperature

- $-55°C$ to $+125°C$ nominal, Oil temperature control system for table and shrouds.

- Logging

- PT100, $8$ channels with all of the available for the device under test,

- Pressure and temperature logging through control system

- Vacuum Flanges

- $1$ DN 10/16 ISO-KF

- $3$ DN 40 ISO-KF

- $2$ DN 100 ISO-K

- $1$ DN 160 ISO-K

- $1$ flanges for manual vent valve (DN 25 ISO-KF)

- $1$ window (DN 100 ISO-K)

- Vacuum Feed Throughs

- List of possible connectors available on request

- Dimensions Mounting Plate

- $670 mm$ diameter

- Material Mounting Plate

- Copper

- Pattern Mounting Plate

- M5 holes with $70 mm$ center to center

- Shroud

- Black shroud

- Optional Equipment

- Residual gas analyzer

Photos: Annelie Klint Nilsson, IRF